Importance of Guideway Design

U.S. MagneticGlideTM

Guideway

Uses repulsive magnetic force from zero energy loss super-conducting quadrupole magnets that permit heavier cargo, electronic switching, and operations on planar track.

• Magnetic fields in passenger

cabin do not exceed natural

earth field.

• Large air gap (4-6 inches.)

inherently strongly stable.

• No weather or seismic issues. • Low construction cost.

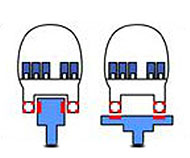

German Guideway

Uses attractive magnetic force from energy consuming conventional electromagnets. Ultra-engineering tolerances and rapid servo control of magnet current required to counteract instability of narrow air gap (1/2 inch).

• Weather and seismic issues.

• Very expensive construction

cost.

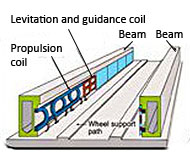

Japanese Guideway

Uses repulsive magnetic force from zero consuming superconducting dipole magnets. Magnetic fields in passenger cabin substantially exceeds natural earth field. Large air gap (4-6 inches).

• Inherently stable.

• U-shape Guideway is sensitive

to snow and ice conditions.

• Very expensive construction

costs.

Maglev 2000 Narrow Beam Guideway

• Full Length (72 foot) Prototype

Narrow Beam Manufactured in

New Jersey.

• Reinforced Concrete Hollow Box

Beam w/Post Tensioning Cables.

• $40,000 cost for first unit;

Projected to be $20,000 in large

scale production.

• Projected to cost Approximately

$4M per Mile (2- Way

Guideway).

• Supports 100,000 lb vehicle with

1/4 inch Mid Span Deflection.

MagneticGlideTM Interstate Freight Carrier Return on Investment is Very Competitive

• Reduce oil imports and trade deficits.

• Save lives and cut health care costs by reducing traffic fatalities and injuries. • Enhance logistics for Defense and Homeland Security.

• Reduce highway and local street maintenance costs by reducing wear and

damage by trucks.

• Reduce fiscal deficits by lower petroleum prices, lower inflation, and greater

productivity in transporting goods and people.

• Enhance environment and health by reducing pollution.

• Increase the export of U.S. manufactured goods.

Click here to return to Features Page